No More

Compromises

Ski design, by nature, has always been a game of compromises. Want a smooth, damp ride? You'll need to sacrifice performance and responsiveness. Prefer a solid ski that carves hard? Brace yourself for a burly, exhausting ride.

Not anymore.

Monobloque™ is a revolutionary technology set to turn the skiing industry on its head. Uniting precision robotics and materials innovation, this proprietary process creates a ski that carves like a Formula 1 car - but rides like a luxury sedan.

What was once unachievable in ski design is now just another day on the slopes—control, stability, and damping—all without compromise.

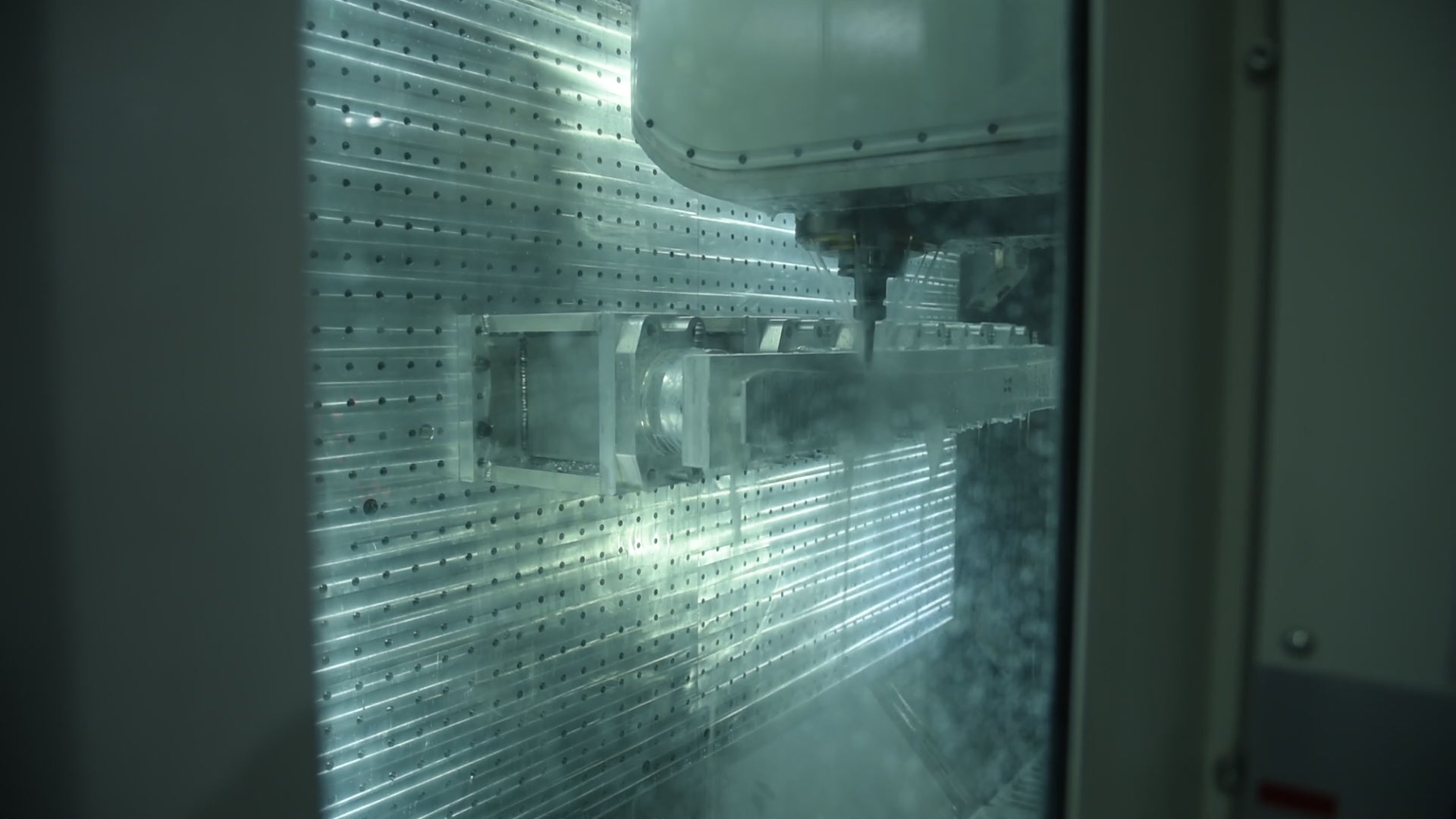

Made By Machines

Traditional hand-made ski manufacturing is an art. With our manufacturing it's science.

Each M1 ski is precision CNC machined from a solid billet of aerospace aluminum alloy, delivering unmatched precision and performance.

REMOVE YOUR

VARIABLE CONDITIONS

Traditional skis are typically constructed from some type of wood-based composite layup. Each brand claims to have the best composite design through either a proprietary material, method, or layup process.

Here's the challenge: it is very difficult to design and manufacture composite skis with precise (and repeatable) flex and torsion characteristics. There is far too much variability in the materials and manufacturing process.

With Monobloque™, though, we can achieve absolute precision over our flex profiles - and, as a result, ski characteristics. Every single time.

Customer reviews

Customer reviews

Precision machined from solid aerospace grade aluminum.

Precision machined from solid aerospace grade aluminum.

Entirely designed & manufactured in the USA.

Robotically machined to within .002" tolerances.

Truly sustainable, recyclable, and environmentally friendly.

TERRAIN-TESTED

TOUGHNESS

Solid aluminum construction ensures that M1's elastic response will endure far beyond traditional skis. It also allows them to stand up to the hardest abuse on the slopes - never delaminate or blow an edge again.

A New Standard in Shock Absorption

There's a reason most performance skis include aluminum (titanal) in their layups: it’s inherently very good at absorbing shock and vibrations.

M1 takes these inherent material properties and leverages them to create a ski that deftly conquers vibration, chatter and bumpy surfaces.

SKI MANUFACTURING'S DIRTY SECRET

The environmental impact of traditional ski manufacturing is profound. Conventional skis rely on complex composites and resins, which are resource-intensive to produce and near-impossible to recycle. The process involves high-energy consumption and generates significant industrial waste, contributing to pollution and environmental degradation.

M1 Skis addresses this challenge by using 100% aluminum, a material celebrated for its recyclability and minimal environmental impact. Our innovative production process minimizes waste and energy usage, setting a new standard for environmentally friendly skiing equipment.